Discovering cracks in your concrete can be a real bummer. It’s like finding a wrinkle in your favorite shirt – you know it’s not the end of the world, but it sure doesn’t look pretty. Whether it’s your driveway, patio, or that fancy concrete countertop, cracks can undermine the aesthetic appeal and even the structural integrity of your concrete surfaces.

Identifying the Types of Cracks

Realizing that you’ve got cracks in your concrete surfaces can be quite the headache, but before diving into repairs, it’s crucial to understand what you’re dealing with. Different types of cracks require different approaches, and correctly identifying them is the first step toward a successful repair.

One of the most common types you’ll encounter is hairline cracks. Just like they sound, these are thin, superficial lines that often don’t pose immediate structural threats but can worsen over time if ignored. They’re usually a sign of natural settling or minor shrinkage as the concrete cures. Despite their benign appearance, it’s best not to overlook these, as water infiltration can eventually turn them into more significant issues.

Next up, we have plastic shrinkage cracks. These appear within the first few hours after pouring the concrete, as it starts to harden and shrink. They’re somewhat wider than hairline cracks and often resemble a spider web spreading across the surface. The key to managing these is prevention, but if they’ve already formed, prompt action is necessary to maintain the structural integrity of your concrete.

Settlement cracks are another beast entirely. They occur when the ground beneath the concrete shifts or settles unevenly, potentially leading to more severe structural damage. These cracks are typically wider and more irregular, indicating that part of the concrete is no longer supported as it was initially intended. Addressing the underlying cause is as important as repairing the crack itself to prevent recurrence.

Lastly, freeze-thaw cracks deserve attention, especially in colder climates. These result from water entering small cracks or pores in the concrete, then expanding as it freezes, which can cause the concrete to crack and surface to flake away. The cyclic nature of freezing and thawing can rapidly worsen these cracks, leading to significant damage over time.

In the table below, I’ve summarized the types of cracks and their key characteristics for quick reference:

| Type of Crack | Appearance | Cause |

|---|---|---|

| Hairline | Thin, superficial lines | Settling, shrinkage |

| Plastic Shrinkage | Spider web-like, wider | Rapid drying, shrinkage |

| Settlement | Wider, more irregular | Uneven ground settlement |

| Freeze-Thaw | Surface flaking, widening | Water infiltration, freezing |

Understanding the Causes of Concrete Cracks

When I first spotted the tiny, spider-web-like cracks creeping across my concrete patio, I knew something was amiss, but I wasn’t quite sure what had caused them. It turns out, there are a few primary culprits behind the cracks in concrete surfaces, and knowing which one is at play is crucial for addressing the issue effectively.

First off, let’s talk about hairline cracks. These are often caused by the natural settling or minor shrinkage of concrete as it cures. In the early days after pouring, concrete is still losing moisture, which can lead to these fine, almost unnoticeable fissures. Although they’re not typically a structural concern, they can be unsightly and may serve as a gateway for moisture, leading to more significant issues if left untreated.

Then, there are plastic shrinkage cracks, which form when concrete starts to harden. If the surface dries too quickly due to high temperatures, wind, or low humidity, it can cause the top layer to crack. It’s like when mud dries in the sun, pulling apart at its surface. These cracks usually appear within the first few hours after pouring and before the concrete is fully hardened.

Settlement cracks are another beast altogether. They occur when the ground beneath the concrete isn’t evenly supported, causing parts of the concrete to sink and crack. This can happen if the soil underneath wasn’t properly compacted before the concrete was poured, or if changes in the soil’s moisture content cause it to shift. Sometimes, even a large tree root growing beneath the slab can be the culprit.

Lastly, let’s not forget about freeze-thaw cracks. These are especially common in colder climates where water can infiltrate concrete, freeze, expand, and then crack the surface when temperatures drop. It’s a cycle that can wreak havoc on concrete over time, creating cracks that expand each winter.

In the table below, I’ve summarized the main causes of concrete cracks:

| Type of Crack | Cause |

|---|---|

| Hairline | Natural settling or minor shrinkage |

| Plastic Shrinkage | Rapid drying of the surface |

| Settlement | Uneven support from the ground below |

| Freeze-Thaw | Water infiltration and freezing in cold weather |

Necessary Tools and Materials

Before diving into the repair process, it’s crucial to gather all necessary tools and materials. Having everything on hand will streamline the job and ensure that it goes smoothly. Let’s explore what you’ll need.

First off, you’ll want to have a chisel and a hammer. These are indispensable for removing loose pieces and debris from the crack before the actual repair begins. It’s important for the concrete to be as clean as possible to allow the patching material to bond effectively.

Next up, a wire brush is essential. After chiseling away the loose concrete, you’ll use the wire brush to further clean the crack and surrounding area. This step ensures that all dust and small particles are removed, providing a clean surface for the repair material.

For deeper cracks, backer rod becomes necessary. This foam material is pushed into the crack to provide a base for the repair compound. It prevents the repair material from sinking too deep into the crack, which could waste material and weaken the repair.

In terms of materials for the repair itself, you have several options depending on the crack’s severity and your personal preference. For smaller, hairline cracks, a simple concrete caulk or sealant is sufficient. These are easily applied with a caulking gun and are great for waterproofing, though they might not be the best choice for larger structural repairs.

For more significant cracks, you’ll need a concrete patching compound. These compounds come in various forms, from mix-it-yourself concrete repair mixtures to pre-mixed formulas. They’re designed to bond strongly to existing concrete, filling in cracks effectively and providing a durable repair.

Additionally, you may require a trowel or putty knife to smooth and level the patching compound once you’ve filled in the crack. A smooth, even surface not only looks better but also ensures that the repair blends seamlessly with the surrounding concrete.

Lastly, protective gear is non-negotiable. Safety glasses, gloves, and dust masks protect you from concrete dust, flying debris, and the chemicals in repair materials. It’s always better to be safe than sorry, so don’t skimp on safety equipment.

Step-by-Step Crack Repair Instructions

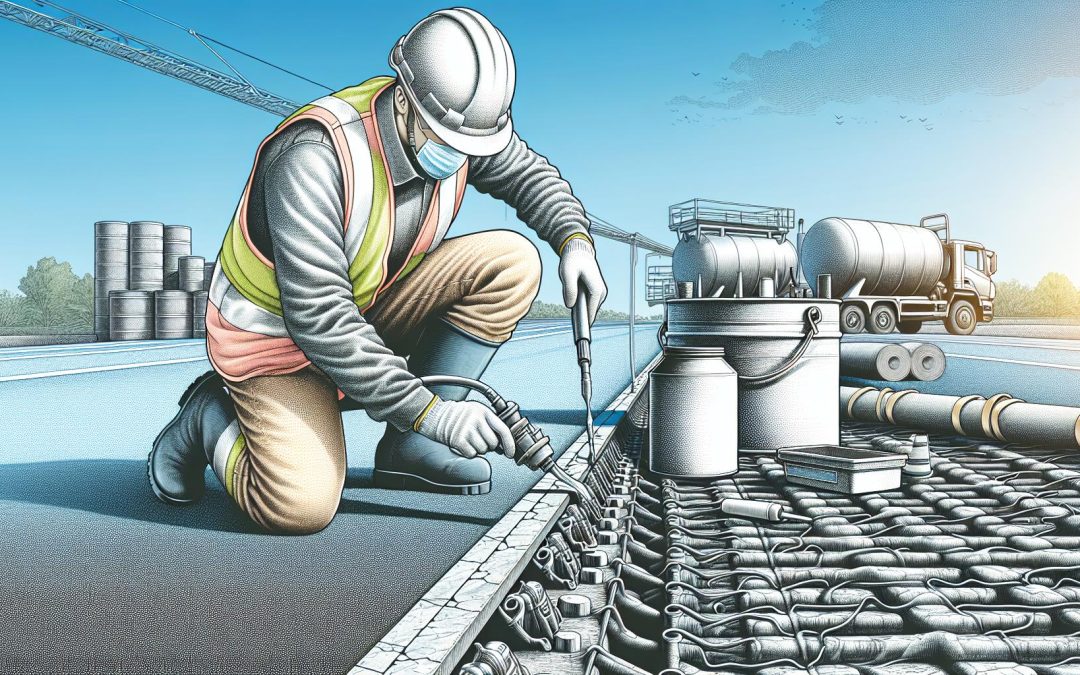

After discussing the necessary tools and materials for repairing concrete cracks, let’s dive into the actual repair process. I’ve broken it down into manageable steps, ensuring you can follow along even if it’s your first time tackling a project like this.

Assess the Crack

First up, I assess the crack to determine the right materials for the job. For hairline cracks, concrete caulk works wonders. But for larger fissures, I rely on a concrete patching compound. It’s crucial to pick the right material to ensure a long-lasting repair.

Clean the Crack

Before filling any crack, it must be clean. I use my wire brush to scrape away any loose concrete, debris, or dust. Sometimes, I’ll even vacuum the crack to make sure it’s as clean as possible. This step ensures the repair materials adhere properly, minimizing future issues.

Prep the Crack

For larger cracks, I prepare them even further by chiseling the edges to create a V-shape. This process might seem counterintuitive, but it actually helps the patching material to stay put. After chiseling, I sometimes insert a backer rod into the crack, especially if it’s deep. This acts as a base for the patching compound, helping me save on material and ensuring a more efficient repair.

Apply the Repair Material

With the crack prepped and ready, I select my repair material. For those narrow cracks, I cut the nozzle of the concrete caulk tube to match the width of the crack and fill it in, smoothing it over with a putty knife. For the broader cracks necessitating a patching compound, I use my trowel to fill the crack, making sure to press the compound in firmly and smooth it out at the surface.

Throughout this process, I wear my safety glasses, gloves, and dust mask to protect myself from any potential hazards. It’s a simple step that goes a long way in ensuring my safety while I work.

Each step of this process is essential in tackling the task of repairing concrete cracks. By following these steps, I’m able to address various types of damage, ensuring a thorough and durable repair. Remember, the key to a successful repair lies not just in filling the crack but in preparing it properly and choosing the right material for the job.

Preventing Future Cracks

After successfully repairing concrete cracks, I’ve learned that prevention is just as crucial as the repair itself. I want to share some valuable strategies and practices that have helped me avoid future cracks, ensuring the longevity of my concrete surfaces.

Regular Maintenance and Inspection

First and foremost, regular maintenance and inspection play key roles in preventing cracks. Over time, I’ve made it a habit to:

- Regularly sweep and clean my concrete areas to remove debris and potential harmful substances.

- Inspect concrete surfaces for early signs of wear and tear, addressing small issues before they escalate.

Proper Installation Techniques

Understanding and implementing proper installation techniques have significantly reduced the occurrence of cracks in my new concrete projects. Here are some essential steps I always follow:

- Ensuring an adequate sub-base: A stable and well-compacted sub-base prevents uneven settling, which can lead to cracks.

- Appropriate concrete mix: I always choose a mix that’s suited for the specific project, considering factors like environment and load-bearing requirements.

- Strategic control joints: Placing control joints at the right locations and distances allows the concrete to expand and contract without causing random cracks.

Environmental Factors

I’ve noticed that environmental factors greatly influence the durability and integrity of concrete. To mitigate these effects, I:

- Apply a sealer: Using a high-quality sealer helps protect the concrete from moisture, chemicals, and temperature variations.

- Ensure proper drainage: Properly directing water away from concrete surfaces prevents water accumulation that can weaken the material over time.

Avoiding Heavy Loads

Concrete has its limits when it comes to weight-bearing. To protect my surfaces, I:

- Avoid placing excessively heavy loads on concrete that’s not designed to support such weight.

- Use caution when moving heavy objects, distributing the weight evenly if possible.

By taking these proactive steps, I’ve managed to not only repair existing cracks effectively but also significantly reduce the chances of new cracks forming. It’s a continuous effort that pays off by extending the life and beauty of concrete surfaces around my home and property.

Conclusion

Repairing cracks in concrete doesn’t have to be a daunting task. With the right approach and a bit of elbow grease, I’ve managed to not only fix the existing issues but also take significant steps toward preventing future problems. Remember, it’s all about being proactive—regular maintenance and smart installation choices go a long way. Whether it’s keeping the area clean, choosing the right concrete mix, or applying sealers, every little action contributes to the longevity and beauty of your concrete surfaces. So roll up your sleeves and give your concrete the care it deserves. Trust me, it’s worth the effort.

Chris Avery the publisher of this website has been a longtime resident of Des Moines. He has lived in the Des Moines area for over 50 years, he is your go-to source for all things concrete in Des Moines and its surrounding areas. It doesn't matter if your location is in Altoona, Ames, Ankeny, DM or any other central Iowa area he can connect you to the right concrete companies.

With a wealth of experience and a vast network of reputable licensed concrete contractors and suppliers, he prides himself on being the bridge between quality craftsmanship and satisfied clients.

For years, he's been fostering strong relationships with top-tier concrete professionals, ensuring that he only recommend the best for your projects. Whether you're looking to build a sturdy foundation, enhance your outdoor spaces with decorative concrete, or undertake a large-scale commercial project, Chris has got you covered.